Superior zinc coatings with reliably corrosion protection for mass-produced goods

Process: Zinc acidic

Application: Barrel application

The HIGH QUALITY ZINC zinc coating system from WHW Hillebrand is characterised by the uniform layer thickness distribution and reliable corrosion protection. The system consists of a metal coating from slightly acidic electrolytes and passivations which protect the zinc layer from white corrosion. If needed, an additional sealant is applied to the passivation which seals cracks and pores.

For different corrosion protection requirements, we offer both thick-layer and thin-layer passivation with a yellow or silver-coloured appearance. The sealants developed by us are tailored to the respective passivation systems, sustainably improve the corrosion protection and increase the mechanical resistance of the surface. For connecting elements, the friction coefficient can be adjusted according to the international standards of the automotive industry.

- Reliable corrosion protection for a long product life

- High white rust resistance

- Excellent looks

- Friction coefficients adjustable according to the requirements of the automotive industry

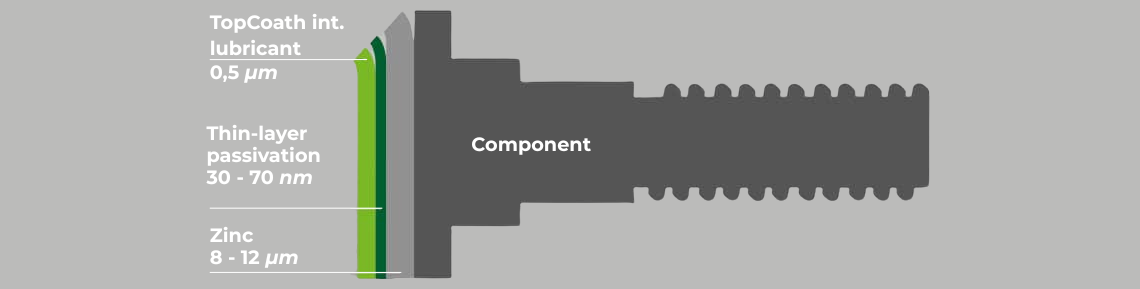

Layer structure – thin-layer passivation

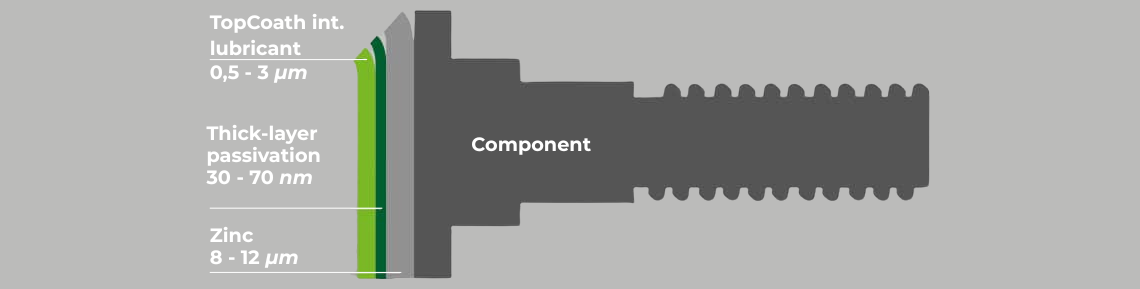

Schichtaufbau – Dickschichtpassivierung/

The system consists of the metal coating from a weakly acidic electrolyte, a passivation which protects the zinc layer from white rust and, if needed, an additional sealant. The passivation is available in thin or thick layer versions, depending on the corrosion protection requirements. The sealant closes cracks and pores.

corrosion protection

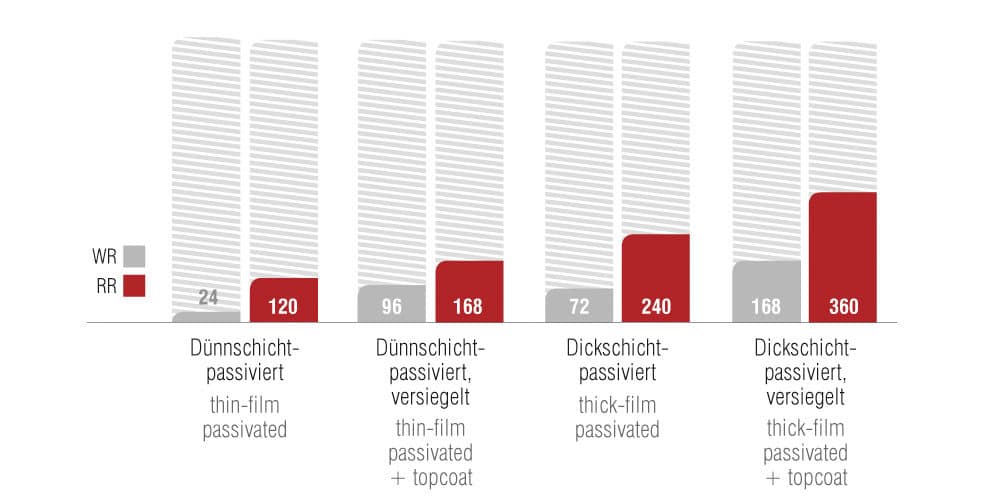

HIGH QUALITY ZINC meets all standardised corrosion protection standards of the automotive industry according to ISO 6227 for zinc systems. By applying special passivations and sealants, these can be raised further. Using a self-developed thick-layer passivation, the corrosion protection is improved without further sealing compared to thin-layer passivation with 24 hours of white rust resistance to 96 hours resistance against zinc corrosion (ISO 6227).

If the thick-film passivation is extended with a special adaptive top coat, you can achieve corrosion protection of 168 hours with regards to white rust, and 360 hours (ISO 6227) against base metal corrosion.

The very efficient and non-sentitive sealants provide high resistance to impact and mechanical stress.