GC TOP 427

High-quality sealant for rack materials – not just for optical demands

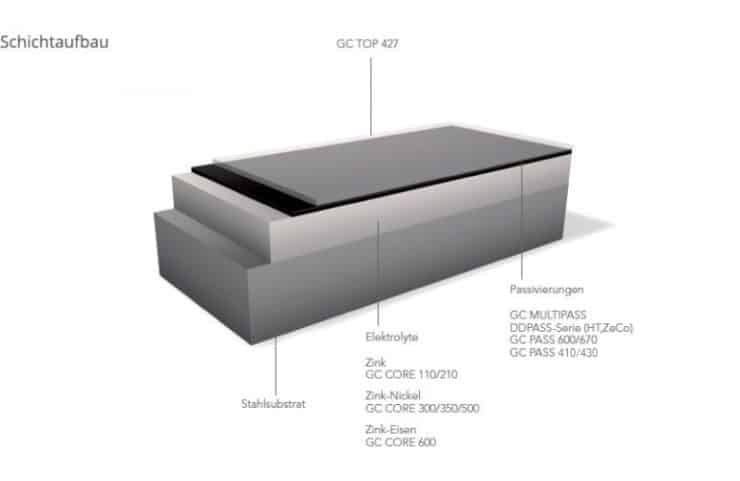

The GC TOP sealing systems developed by Hillebrand Chemicals (Top Coats) offer a wide range of applications for visually attractive surfaces with simultaneously improved corrosion protection. They are designed to be used with GC PASS passivation. On electro depositions the combination of these two coatings influences the chemical and mechanical resistance of the entire system.

GC TOP 427 is a modern, water-based sealant for visually pleasing surfaces with excellent corrosion protection performance.

The transparent coating material is universally applicable – both on black and transparent passivated zinc and zinc-alloy deposits. Of particular note is the very good corrosion protection on black passivated ZnNi surfaces: White rust is not formed even after 360 hours of stress, and the 720 hours required for red rust in the standards are also exceeded.

Handling the product is very simple. The sealing product is delivered in two components meaning it can be flexibly adapted to the existing plant technologies. Drying is possible from 50 °C. Higher temperatures (over 70 °C) allow the corrosion protection to be further improved.

Even a specification pre-conditioning prior to the salt spray test does not reduce the corrosion resistance of the coating system.

Pale or iridescent black passivated surfaces get a uniform fully black look.

GC TOP 427 is suitable for cobalt-free coating systems.

Corrosion resistance in accordance with DIN EN ISO 8227 depending on the substrate:

- Zinc-iron 8–12 µm, black passivated, GC TOP 427 WR > 240 h RR > 720 h

- Zinc-nickel 8–12 µm, black passivated, GC TOP 427 WR > 360 h RR > 1000 h