FÜR SICHERE VERBINDUNGEN

FOR SECURE CONNECTIONS

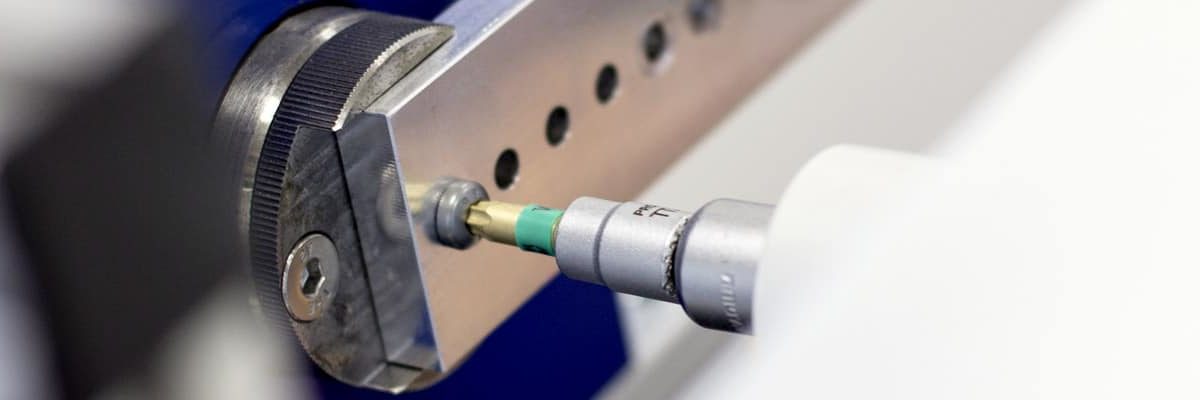

There are various test benches for targeted product development of fastening elements available in the CIT. Using these ones, the required information about friction behaviour and other parameters of the coated components can be determined. This enables preventive process monitoring as well as targeted support for development projects both for us and for our customers. This means we are in a position to intervene quickly and flexibly in the event of deviations from customer specifications or standards.

Fastening elements department – Functionality to increase performance

Hillebrand Chemicals’ products do not just ensure a significant increase in corrosion protection for fastening elements, rather they also increase the performance of your nuts and bolts. Without our tailored and intelligent process chemistry, suitable friction properties and optimised multiple tightening performance could not be achieved.

The exact measured values and corresponding expertise are available within our Fastening elements department. Measurement and evaluation of screwing in torques, unscrewing torques, screwing on torques and other ones are carried out here. In this way we can develop new functional coatings to work against steel, aluminium or painted friction partners.

Close customer cooperation and the short information channels between the other specialist departments within WHW Hillebrand Group allow targeted production development. You benefit from our experience

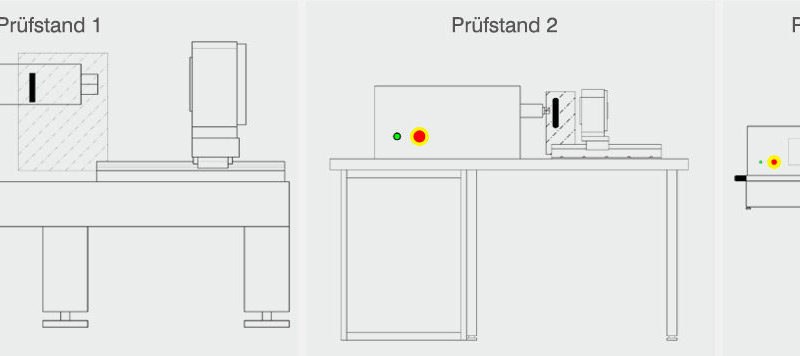

Test benches for friction coefficient tests

Test bench 1

- Dimensions: M27-8.8 – M39-10.9

- Tightening speeds: max. 20 rpm

- Measurements taken: Pre-load force / total torque / frictional torque on the support surface / rotation angle

Test bench 2

- Dimensions: M6-8.8 – M16-12.9

- Tightening speeds: max. 250 rpm

- Measurements taken: Pre-load force / total torque / frictional torque on the support surface / rotation angle

Test bench 3

- Dimensions: M4-8.8 – M6-12.9

- Tightening speeds: max. 250 rpm

- Measurements taken: Pre-load force / total torque / frictional torque on the support surface / rotation angle

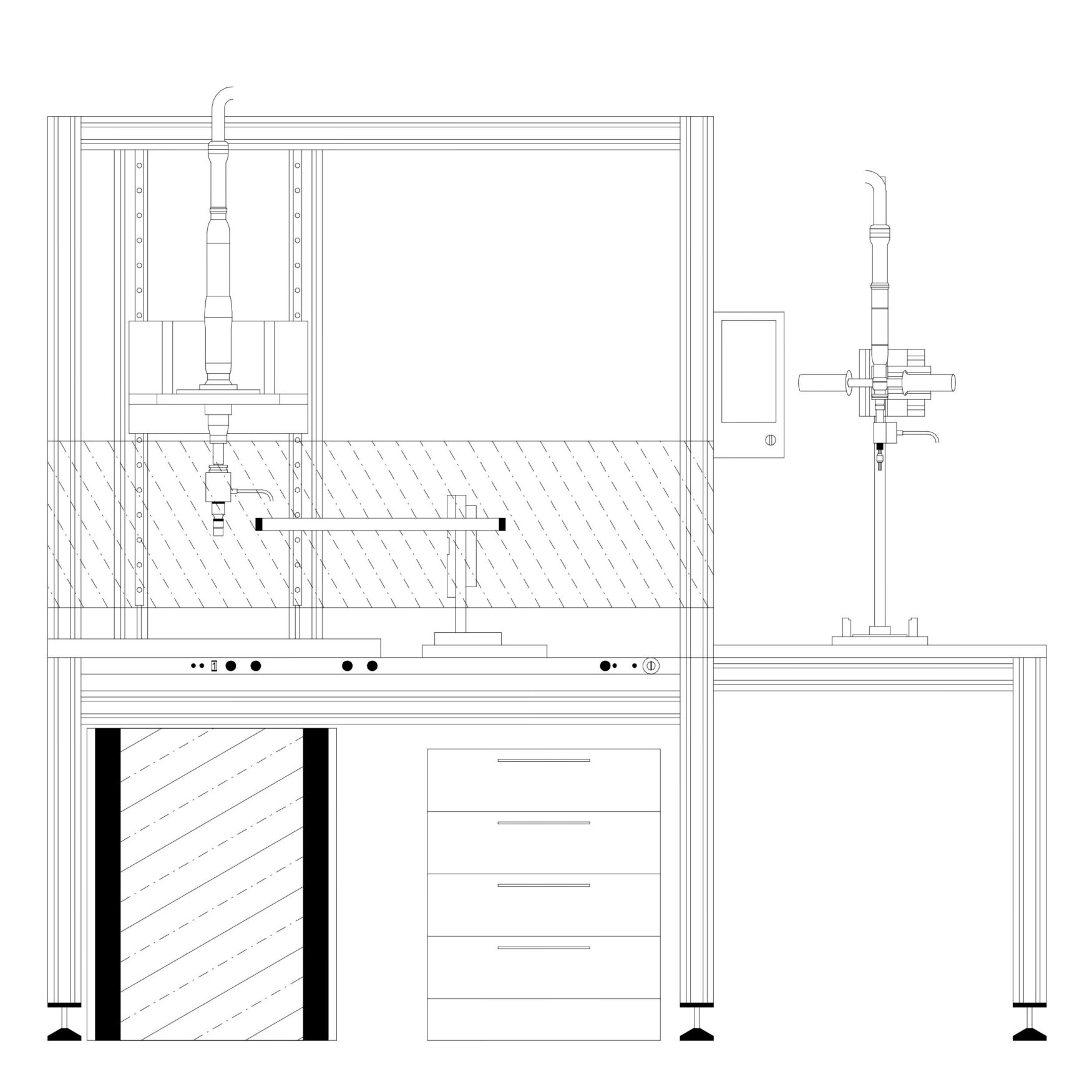

Test bench for tension tests

Small working range

Dimensions: ø2 – M6-12.9

Tightening speeds: max. 1700 rpm

Measurements taken: Torque / rotation angle

Tightening method: Single and multi-stage, torque control, torque control + rotation angle control

Large working range

Dimensions: M8-8.8 – M14-12.9

Tightening speeds: max. 350 rpm

Measurements taken: Torque / rotation angle

Tightening method: Single and multi-stage, torque control, torque control + rotation control, yield point control

Behaviour under temperature load

- Heat release behaviour under temperature

- Friction change after temperature load