ZINC-IRON COATINGS WITH HIGH-QUALITY CORROSION PROTECTION

Process: Zinc-iron alkaline Technology: Barrel and rack application

With BRILLIANT BLACK we offer you a zinc-iron surface system for mass-produced and rack goods which can be used wherever higher corrosion protection with an attractive surface design is needed. The system consists of the metal coating using an alkaline zinc-iron electrolyte with a homogeneous iron incorporation rate between 0.3 and 1.0 %, a black passivation process to protect the zinc-iron layer from white rust corrosion, and an additional sealing process which is applied to the passivation closing any cracks and pores at the same time. The sealants developed by us are tailored to the respective passivation systems, sustainably improve the corrosion protection and increase the mechanical resistance of the surface. For connecting elements, the friction coefficient can be adapted according to the international standards of the automotive industry.

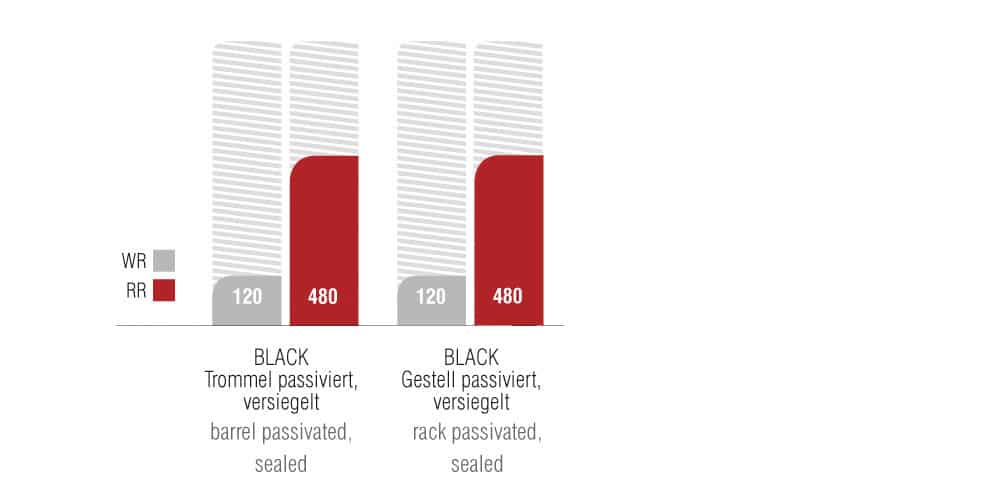

• Higher corrosion protection of > 480 hours in accordance with DIN EN ISO 9227 • Very well suited for complex geometries • Homogeneous and overall black appearance • Good white rust resistance • Uniform thin layer thickness

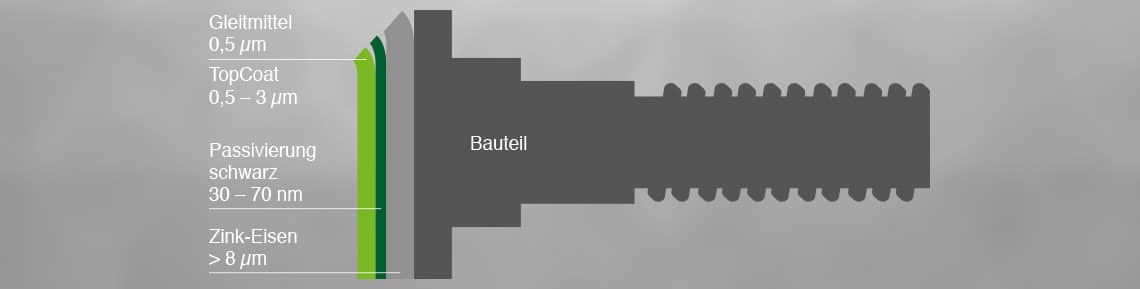

Layer structure

WHW Hillebrand BRILLIANT BLACK consists of a zinc-iron alloy electro-deposited from an alkaline bath with a layer thickness of >8 µm. It has a homogeneous iron incorporation rate of between 0.3 and 1.0 % and a black passivation system which helps protect against premature formation of grey haze and white rust.

Corrosion protection

BRILLIANT BLACK has a very homogeneous coating thickness distribution and can be used for technical and functional surfaces. Compared to conventional zinc surfaces, the corrosion protection is significantly better even with very thin layer thicknesses. Following the coating, a Cr(VI) passivation can be applied which protects the surface from zinc corrosion. Subsequently applied sealants and top coats further increase the corrosion protection.