Nano-sealing with optical and technical attributes

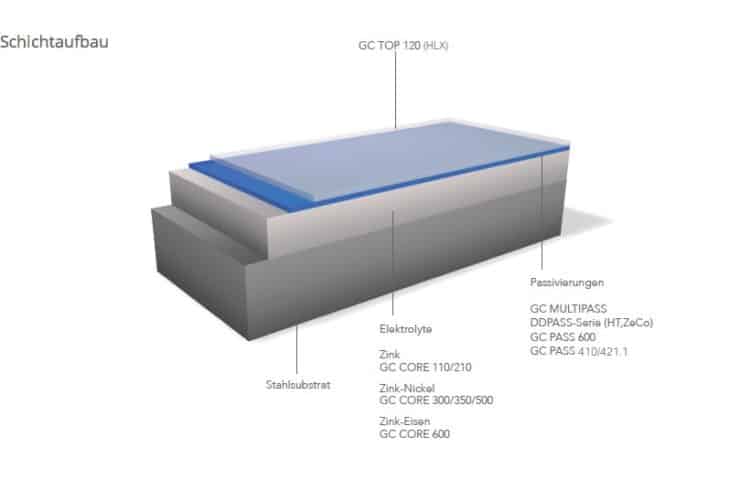

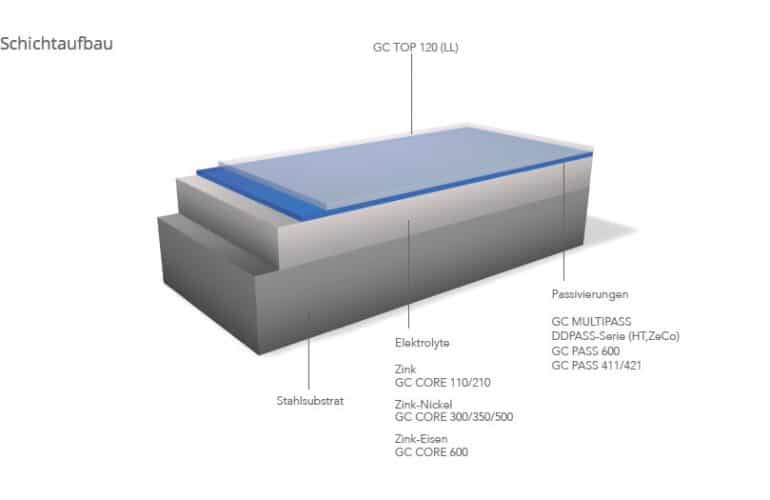

The GC TOP sealing systems developed by Hillebrand Chemicals offer a wide range of applications for visually attractive surfaces with simultaneously improved corrosion protection. They are designed to be used with GC PASS passivation. On electro depositions the combination of these two coatings influences the chemical and mechanical resistance of the entire system.

GC TOP 120 is a particularly high-quality sealing product. It is water-based with organic and inorganic components for centrifuge and barrel applications. Specially transparent passivated zinc and zinc alloy deposits achieve a high corrosion protection through the sealing film.

The percentage of functionalised nano-particles distinguishes GCTOP 120 from customary sealants on the market. The modified binder system permanently prevents infiltration on damaged surface areas. The dry seal film is absolutely transparent and gives the galvanized part a particularly noble appearance.

GC TOP 120 is ideally suited for processing in dry centrifuges with hot-air injection between 80 and 120 °C. The process is usually set at 25 to 80 %.

GC TOP 120 is not prone to sticking and thus ensures the trouble-free processing of flat superimposed part geometries. The dry film has a layer thickness of 0.8 to 1.5 µm and suppresses the iridescence effects of the passivation.

GC TOP 120 very clearly delays the driving forces of the infiltration in the event of a breach of layers.

Opposing layer properties such as ductility and hardness open up additional possible applications for the sealing product. Damage to parts during reloading processes are thus avoided.

Corrosion resistance in accordance with DIN EN ISO 8227 depending on the substrate:

- Acid zinc 8–12 µm, DISP, GC TOP 120 WR > 240 h RR > 480 h

- Zinc-nickel 8–12 mm, transp. passivated, GC TOP 120 WR > 300 h RR > 1000 h

GC TOP 120 offers high resistance to cyclic corrosion tests.

The lubricated version, GC TOP 120 HLX offers excellent friction properties and a defined friction coefficient µtot of 0.10 ± 0.02 even over multiple tightening processes.